-

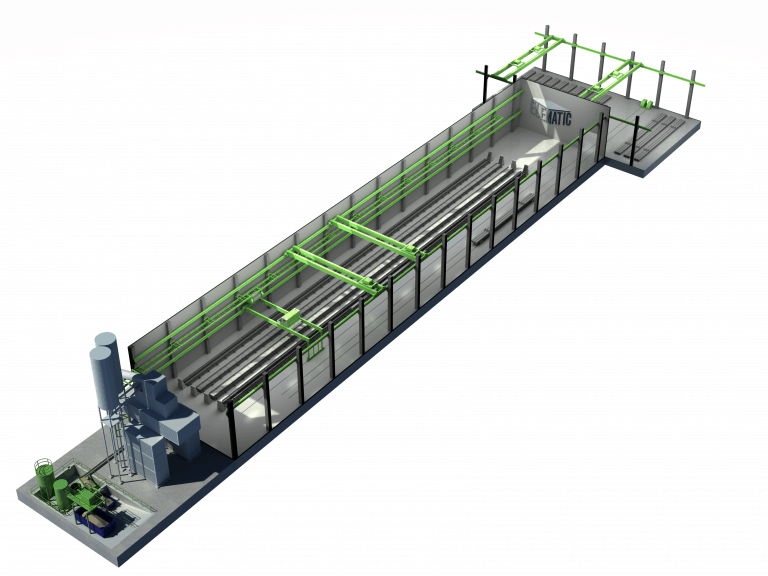

The Elematic frame line offers a highly productive way to manufacture high quality prestressed or reinforced columns, beams, T-beams and L-beams that provide unlimited flexibility in design, shape and application. Beams and columns are produced indoors with high-strength concrete creating a quality, strong and durable product with no need for extra fireproofing.

The frame line covers the entire process from concrete batching to storage yard management. The line needs an area of 3,000 m2 for production, and the total land area required for the operation is 10,000 m2.

-

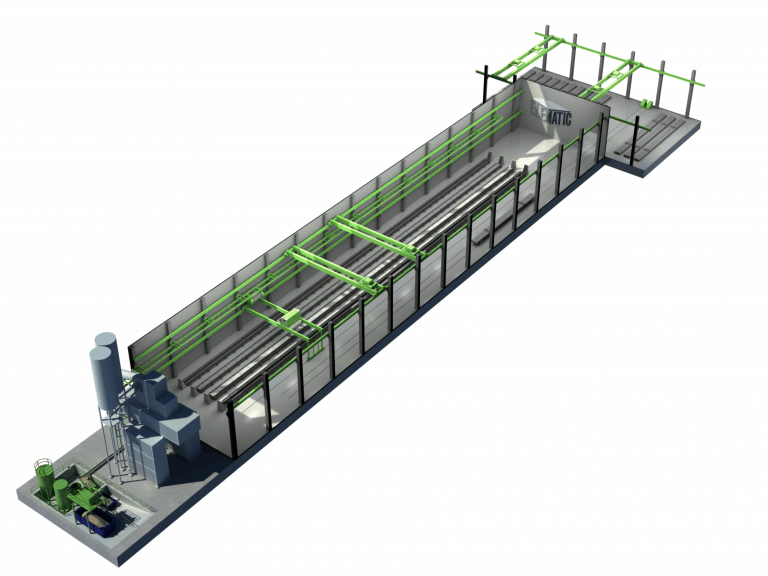

The Elematic combined hollow core and frame line offers a highly productive way to manufacture high quality composite slabs, hollow core slabs, TT-slabs, beams and columns with one production line. The line offers a high capacity utilization rate with wider product portfolio.

The combined hollow core and frame line covers the entire process from concrete batching to storage yard management. The line needs an area of 3,000 – 5,000 m2 for production, and the total land area required for the operation is around 10,000 m2.

-

The Elematic Acotec installation wagon is used to move the Acotec panels at the construction site during installation. The ergonomic wagon makes Acotec panel installation quick and easy.

Do you have questions? Contact us!

or