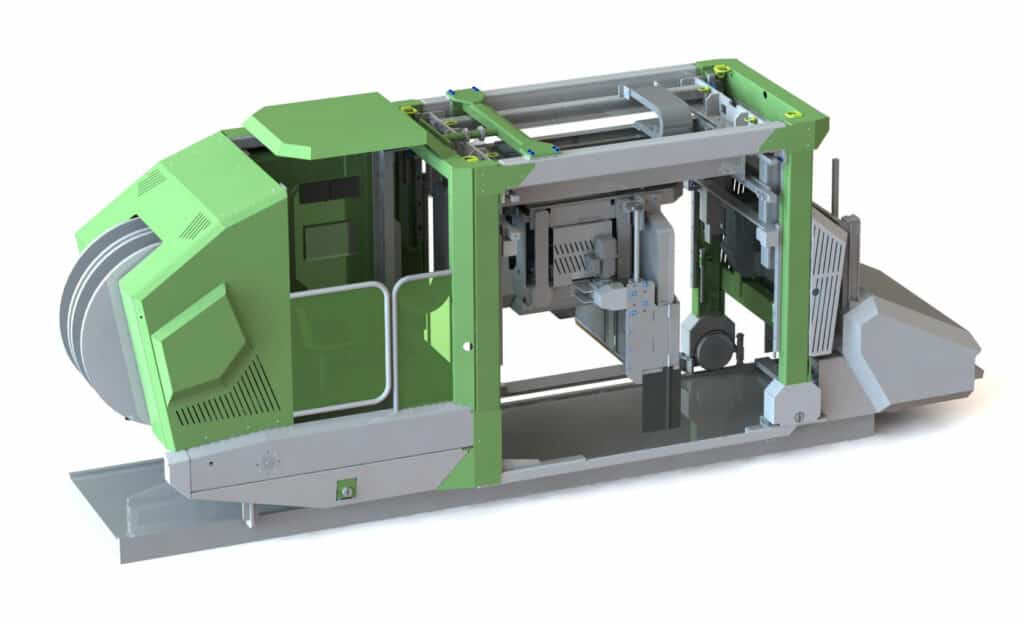

Sawpreparer S5

The Elematic Sawpreparer S5 is a semi-automatic machine for cutting hollow core slabs, brushing and oiling casting beds and pulling pre-stressing strands.

The machine can also cut solid slabs and ribbed slabs.

Download brochure

Sawpreparer S5-500p 2022

| Width | 1650 mm |

|---|---|

| Length (incl. brush) | 6700 mm |

| Height | 2560 mm |

| Weight (with brushing units) | 7000 kg |

| Blade diameter alternatives up to | 1350 mm |

| Saw transport speed, stepless | 0-0.67 m/s |

| Brushing/strand pulling speed | 0.5 m/s |

| Connecting power | 73 kW |

The Elematic Sawpreparer S5 is unique combination of four separate precast production functions in one machine: cutting, cleaning, strand pulling and oiling. The machine cuts slabs of max. 1250 mm in width and max. 500 mm in height. Slabs can be cut at any angle: crosswise, longitudinally and in any angle between: Crosswise (90°), diagonal (0°-180°) and longitudinal (0° or 180°) cuts.

The machine includes a powerful saw, a laser pointer for fast positioning and automatic cutting programs to optimize the cutting cycles. The blade is inverter-driven, which makes it easy to change the speed to fit various blade sizes and types. The modern calibration system ensures cutting accuracy.

New features in 2022 model:

- Max slab size 500mm (earlier 400mm)

- Telescopic blade cover for added safety (blocking shooting diamond cutting pieces and noise)

- New blade movement and drive mechanisms for easier maintenance

- Simpler and more reliable mechanisms

- Reduced height: can fit in lower production halls

The Sawpreparer S5 uses four-wheel drive, which gives it a high traction force and enables it to pull several strands simultaneously. It cleans beds quickly and the integrated water sprays wash the slab surface after cutting. The machine features an oil tank and nozzles to spread oil evenly below the strands, as well as hooks to prevent the strands becoming contaminated with oil.

OPERATION

All operations in the Sawpreparer S5 are electrically driven, meaning that the machine is hydraulics-free and therefore needs only minimum maintenance. This translates into high reliability.

The advanced, durable graphical user interface is also suitable for outdoor operation. The user interface enables stepless adjustment of the blade rotation speed, feed speed and machine forward/reverse speed. It can also store slab parameters and four product-specific cutting programs for crosswise cuts. The running hours of the machine and of the blade are stored automatically.

The machine is designed for low part wear and convenient part changes.

BUILT-IN SAFETY

Like all Elematic machinery, safety features are built in. The Sawpreparer S5 has a safe cockpit with a transparent shield and a camera system for situational awareness. The machine features derail protection, reducing the risk of derailing and the risk of the saw falling over. The machine is also equipped with a fast blade stop and the control system prevents the saw blade being lowered when it is not rotating.

The machine meets all EC Machine Directive requirements. It is delivered with comprehensive operator, maintenance and safety manuals in the required language.

COMPOSE

The Sawpreparer S5 runs along the rails on a casting bed and needs one person to operate it.

The Sawpreparer a fully electric driven machine. The power is fed via a cable coiled on a cable drum. The water is fed via a hose coiled on a hose reel.

Compatibility

Benefits

-

Fast cutting at any angle

-

Easy maintenance

-

One machine, many functions

A part of

Precast products

Services

Do you have questions? Contact us!

or