PRO Floor

The Elematic PRO Floor is the ideal choice when an annual production capacity of 100 000 – 350 000 m2 is required. It can produce a range of product types, including extruded or slipformed hollow core slabs, pre-stressed ribbed and half slabs 1 200 mm wide and between 120 – 500 mm thick, as well as T-beams.

As with all Elematic production lines, the PRO Floor can be, and almost always is, customized to suit the needs of a specific factory.

Download brochure

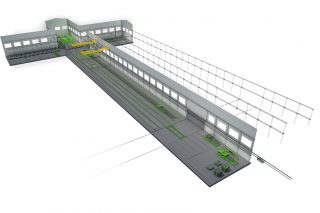

PRO Floor line*

| Theoretical capacity | 1080 m2/day (one casting) |

|---|---|

| Personnel | 7 |

| Production area | 4000 m2 |

| Land area | 6500 m2 |

| No. of beds | 6 |

| Max. end product height | 500 mm |

| Min. end product height | 120 mm |

| End product width | 1.2 m (1.5 and 2.4 m also available) |

| *All figures are estimates |

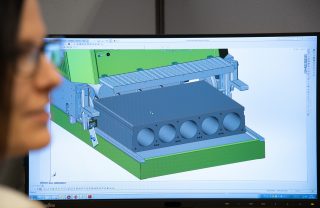

The Elematic PRO Floor production line features mechanized production technology, a medium level of automation and sophisticated machinery, with Extruder P7 or Slipformer P7 at its core.

TAKE A LOOK AT A 3D MODEL OF THE FACTORY CONCEPT

When an Extruder P7 is used, the concrete consumption of the PRO Floor is minimized thanks to the machine’s efficient shear compaction technology. The concrete transportation is entirely automated, and the beds are prepared using just one machine and one operator, for significant savings in time and money.

The PRO Floor features high-precision beds that have long-lasting steel surfaces and an integrated heating system to speed up curing and promote solid bonding between the concrete and pre-stressing strands, even in warm climatic conditions.

The PRO Floor needs a 4 000 m2 area for production, and the total land area required for operation is 6 500 m2. It has 6 x 150 m beds and it requires 7 personnel to operate the line.

PROCESS DESCRIPTION

Precast slab production on the PRO line takes place in 10 functional steps:

- Batching and mixing

- Concrete transportation

- Concrete distribution

- Bed preparation

- Pre-stressing

- Casting

- Slab modifying

- Curing

- Cutting

- Storing

The process starts with bed preparation, which is carried out by a Preparer. First, the Preparer cleans and oils the casting bed and then pulls the pre-stressing strands. The strands are then pre-stressed with a bundle stressing unit.

The casting machine is then lifted onto the bed and filled with concrete. The concrete itself is transported using a concrete transportation shuttle to the distributor and then onwards to the hopper of the casting machine. The automatic system ensures that there is always concrete in the hopper. The fresh slab is then modified manually with markings and openings, and then covered with a tarpaulin to maintain the optimal curing conditions. After curing, the Saw is lifted onto the bed and the slabs are cut to length according to the production plan. The cut slabs are lifted from the bed and moved to storage.

The whole process is managed and controlled by the Elematic Plant Control.

SUSTAINABILITY

PRO Floor line is designed with environmental issues in mind. Cement use is minimized by the efficient compaction of the Extruder casting machine. In addition, the production process does not produce any toxic waste.

SAFETY

All machines on the PRO Floor line meet EC Machine Directive requirements. The machinery is designed to keep noise levels low and enhance safety with their even outer surfaces. The line comes with thorough and clear user, maintenance and safety manuals in the required language.

Related products and services

Benefits

-

Low cement consumption with shear compaction

-

Wide product range

-

Fast curing with integrated bed heating

Other floor production lines

Precast products

Software

Do you have questions? Contact us!

or