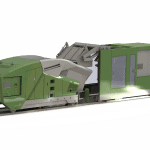

Extruder E9

The Extruder E9-1200e is an extrusion casting machine that produces hollow core concrete slabs of 120 mm – 500 mm thick and 400 mm – 1200 mm wide. It is the flagship of the best-in-the-industry extruders and sets a new benchmark for high-speed casting – 2,7 meters per minute – with low production costs.

Download a brochure

Extruder E9-1200e 2019

| Width | 1670 mm |

|---|---|

| Height (slab heights 120-320 mm) | 2140 mm |

| Height (slab heights 320-500 mm) | 2180 mm |

| Length (with cable drum) | 5100 mm |

| Weight (depending on options) | 6300-9450 kg |

Casting speed*

| 8/150-160 | Min. 2.1 m/min |

|---|---|

| Max. 2.7 m/min | |

| 4/500 | Min. 1.1 m/min |

| Max. 1.7 m/min | |

| * Depending on slab thickness |

With the industry’s highest casting speed of up to 2.7 meters per minute – 30% to 70% faster than its predecessors – the new Extruder E9 perfectly responds to requirements for fast slab production. The high casting speed means it produces 8 to 10 cast beds in the same time that was previously used to produce only 6 cast beds, producing as many as 18 cast beds per day.

The Extruder E9 is a multi-product machine. In addition to standard hollow core slabs, it is also well suited to producing narrow hollow core slabs (filler slabs), piles & poles, solid slabs, wing-slabs, walls and boundary walls, sockle slabs and stadium slabs.

TAKE A PRODUCT TOUR WITH THE PRODUCT DIRECTOR

CASTING AND COMPACTION

The Extruder E9 achieves its high casting speed thanks to the smart design of the extruding screws, optimized casting parameters and independent screw drives. The machine features a 2nd generation automatic compaction control system with the resistance of the levelling beam used as a new, additional input parameter. Together with the independent casting screws this guarantees a balanced casting process because the concrete is fed more evenly throughout the whole slab cross section. The casting process is carefully monitored and controlled, leading to further increases in slab quality.

Changing slab-type is fast; thanks to the modular structure of the Extruder, you only need to change nozzle modules or exchange parts.

INTELLIGENCE

The Extruder E9 has numerous sensors that continuously feed data to an on-board computer. The stored data can be used and analyzed in different applications, remotely or on-site.

The Extruder E9 features an easy-to-use visual user interface. All casting parameters can be saved or recalled automatically, and several sets of casting parameters can be saved for each nozzle module. In addition to using the Metric system, it is easy to operate with the Imperial system as well. The machine is also equipped with concrete ordering automation.

In addition, the machine displays running hours for the power module and nozzle modules to assist maintenance scheduling, and it produces clear reports for uptime, down-time, alerts, faults etc. The operating manuals are also available through the user interface, too.

BUILT-IN SAFETY

Like all Elematic machinery, safety features are built in. The Extruder E9 has a flat design with an antiskid system on the service platform and the foldable steps. The hopper measures the volume of concrete so there is no need to climb on the machine. The lifting hook can be attached from the service platform at the rear of the machine.

OPERATION

The extruder moves on four wheels on the side rails of the casting bed. It is pushed forward by the reaction force of the concrete feeding screws. Driving gear moves the extruder when it is not casting. Compaction is carried out using the shear compaction method.

OPTIONS

Concrete recycling system

Maintenance tools

Service platform light

Service platform

Cable drum for max. 160 m cable 550 1300

Cable drum for max. 200 m cable 550 1320

Flexible cable for power input w/o plug 550 1410

Fixed male plug for power feed via distributor 550 1500

Water feeding system 519 1100

Extension part for concrete hopper 519 1200

Concrete ordering 519 2200

COMPOSE

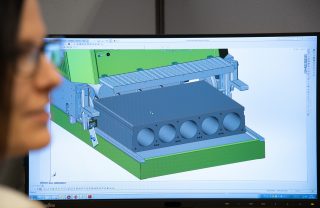

The Extruder E9 consists of a universal power unit and a slab-type specific nozzle module. The E9-1200e power unit is designed to run compatible E9 nozzle modules. In addition, a cable drum with a cable or a power connector is needed to run the machine.

The E9-1200e power unit consists of a removable concrete hopper and an operating unit with motors.

Compatibility

Benefits

-

High casting speed

Casts up to 2.7 meters per minute

-

Easy to operate

Modern visual user interface

-

Automatic concrete recycling with Modifier E9

A part of

Goes with

Precast products

Software system

Do you have questions? Contact us!

or