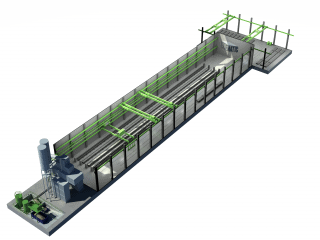

Casting bed for beams and columns

Elematic casting bed for beams and columns is designed for the production of columns, beams, T-beams and L-beams that can be either prestressed or reinforced.

Casting bed for beams and columns

| Available widths | 1.2 m, 1.4 m, 1.8 m and 3.4 m |

|---|---|

| Thickness of the surface plate | 10 mm |

The casting bed for beams and columns is manufactured in a workshop to tight tolerances. Its rigid all-steel structure is welded to the frame construction. It has longitudinal U-profiles. The bed features an integrated heating system to speed up curing. Heating pipes are installed under the bed surface, and hot water is used as a heating medium. The bed is delivered in 12 m modular, fast-to-install sections. The total bed length is defined according to case-specific requirements.

The bed is available in the following widths, maximum loads, and beam/column widths (+2x300mm for column console on both sides):

- width 1.2 m, max. load 3,360kg/m², max. product width 800mm

- width 1.4 m, max. load 3,360kg/m², max. product width 1,000mm

- width 1.8 m, max. load 3,360kg/m², max. product width 1,400mm

- width 3.4 m, max. load 2,000kg/m², max. product width 2 x 1,400mm

COMPOSITION

The casting bed for beams and column is made from U-beams, stiffeners and a durable 10 mm straight rolled acid treated surface plate. Fastening plates for fastening of triangle supports for side forms are attached to the outer surface of the edge beams of the bed. The c/c spacing of the plates is 2,000 mm.

Note that vibrating can take place only with poker vibrators. There is no possibility for fixed vibrators.

OPTIONS

Prestressing abutments depending on the bed and product width:

- P7-750 (max product width 1000mm, max. pre-stressing force 750t)

- P7-750-1,400 (max product width 1400mm, max. pre-stressing force 750t)

- P7-2 x 500-2X1,400 (max product width 2 x 1,400mm, max. pre-stressing force 2 x 500t)

Compatibility

Do you have questions? Contact us!

or