Acotec PRO

The Elematic Acotec PRO production line offers straightforward, fast and profitable production technology for light, non-load bearing, room-high partition walls called Acotec. The line covers the entire production process from concrete batching all the way to the overnight storage.

Download a brochure

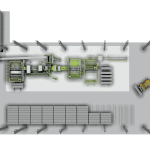

Acotec PRO line

| Theoretical capacity | 100 m2/h |

|---|---|

| Personnel | 2-4 |

| Production area | 900 m2 |

| Land area | 3000-5000 m2 |

| No. of plates | 500 pcs |

| End product length | 2200-3300 mm |

| End product thickness | 68-120 mm |

| End product width | 600 mm (300 mm also available) |

The Acotec PRO line produces light, non-load bearing, room-high partition wall panels 2 200 mm to 3 300 mm long and 68 mm to 120 mm thick. The width of the panel is 600 mm, or as an option, 2 x 300 mm.

The PRO is an advanced line with a production capacity of 100 m2/hour*. On an annual basis, this give it a capacity of 150 – 210 000 m2 in one shift operation – enough to build partition walls for 1500 – 2000 dwellings.

The line only needs an area of 900 m2 area for production, and the total land area required for operation is 3 000 – 5 000 m2. It requires 2 to 4 personnel to operate the line. The line can also be installed in existing facilities.

*Peak capacity. Maintenance stops (2 to 4 per shift) etc. not included.

PRO TECHNOLOGY

The Acotec PRO features automation in all the main functions: sawing, trimming, stacking, restacking, cleaning and oiling, plate handling and pallet circulation.

The key equipment on the PRO line include a fast, reliable and easy to maintain stationary extruder with three vibrators, and compression and levelling equipment. The extruder is equipped with standard panel thickness sets of 68/75/85/92/100/120 mm according to selection.

A moving circular saw is installed on a roller conveyor which cuts at a speed of 10 m/min. The included trimmer can trim up to 20 cm from the panel length, and the recycling function recycles trimmed pieces and rejected slabs to decrease the amount of waste.

The stacker stacks the extruded products and their backing plates in 4 to 10-piece stacks on steel pallets and transfers the pallets for precuring. The restacker lifts the finished products and separates B-quality panels. A plate handler feeds the plates back into the production process, guaranteeing the non-stop operation of the extruder.

ACOTEC LINE TECHNOLOGY

Like all Elematic Acotec lines, the PRO line is simple to install, run and maintain. It features an advanced production control system and a simple, modern user interface which displays detailed data about every function in the process. Each line is constructed from proven, standard components for highly reliable operation.

The line’s modular structure and integrated electricity with ETHERCAT bus system guarantee a short installation and start up time.

PROCESS DESCRIPTION

Acotec panel production on the PRO line takes place in the following steps:

- Batching and mixing

- Casting

- Cutting

- Stacking

- Precuring

- Restacking & plate handling

- Cleaning (manual, automatic optional)

- Returning pallets

- Packing and delivery

The Acotec panel production process starts with batching and mixing of concrete at an automatic batching and mixing station. The aggregates are automatically batched into the mixer, after which cement and water are added into the mixture. After mixing, the concrete batch is fed to the conveying system and conveyed to the line’s hopper.

The panels are then formed by a continuously operating extruder. The concrete is compacted onto thin base molds which are then automatically fed into the extruder as a continuous ribbon. The extruder compacts the concrete with extrusion screws and the top surface of the product is vibrated by a vibrating plate.

After extrusion, the panels are cut according to the base mold length. The circular saw cuts the fresh concrete on each base mold seam on the fly. When a piece needs to be trimmed, the fresh product stops at the specified point, and the manually adjusted circular saw cuts off the necessary amount. After this, the cut panel, together with the supporting plate, is pulled to the stacker, stacked into precuring stacks and moved to the precuring area, where the temperature should be above +10°C. The cut panel can be transferred either using an automated conveyor system, or with a forklift or a crane. The stacks stay in precuring for 15 to 24 hours.

After precuring, the panels are removed from the base molds. The molds are returned to production after passing through a cleaning and oiling unit, and the panels are restacked in stacks of 4 to 10 units for delivery. The delivery stacks are strapped and preferably wrapped before transportation to delivery storage. The stacks must stay in delivery storage for at least 14 days before being transported to a construction site.

The base plates are cleaned automatically before being returned to the production process.

SUSTAINABILITY

The Acotec production method is environmentally friendly. The raw materials used are natural materials – just water, sand, cement and lightweight aggregate. The production does not need any additives or chemicals.

The concrete waste produced is kept to a minimum: trimming pieces and rejected panels can be recycled back into the production process.

SAFETY

All machines on the Acotec PRO line meet EC Machine Directive requirements. The line is equipped with multiple safety light curtains and all doors have safety sensors. The machinery is designed to keep noise levels low and ensure safety with flat outer surfaces. The line comes with thorough and clear user, maintenance and safety manuals in the required language.

OPTIONS

Concrete supply

Product module 8/68, 8/75, 6/92, 6/100, 6/120

Thickness set 68, 75, 92, 100, 120

Splitting set 2 x 300 / 68, 75, 92, 100,120

Extra mold plates

Extra steel pallets

Batching and mixing plant and concrete transport system

Service hoist

Panel weighing

Compatibility

Benefits

-

Fast return on investment

-

Easy to install, run and maintain

-

Low operational costs

Other Acotec lines

Additional equipment

Precast products

Do you have questions? Contact us!

or