Pile

Driven piles, also known as displacement piles, are underground supporting precast products. Piles take on foundation loads and transfer them to soil or rock layers that have sufficient bearing capacity. The precast pile is typically a long, slender, columnar element.

Precast concrete pile – an industrialized piling solution for deep foundations

Precast piles have excellent adaptability and resistance to corrosion.

Precast concrete pile production is high-speed. The daily output can reach even 3 km of ready-to-install precast concrete piles. High-quality steel joints are used to quickly splice the piles to the required length on the construction site.

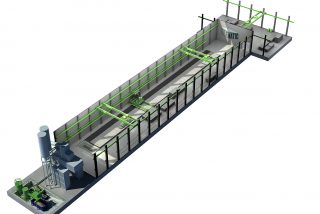

Piles can be extruded on hollow-core slab beds or a cast special Foundation line. Before casting, the reinforcement is put in the molds manually or automatically by a robot welding machine. Normal gray or self-compacting concrete is used for pile production. Elematic offers equipment for producing square precast concrete piles of sizes from 200 x 200 to 400 x 400 mm. Pile molds are durable, rigid, welded steel structure that keeps the end product straight and even.

Application

Driven precast piling is one of the most cost-effective solutions for deep foundations. Piles are stable in soft squeezing soils and can densify loose soil. Piles can be used for any building structures where loads and soil conditions require a deep foundation. Piles are typically used in large structures, such as offshore or bridge construction, embankments, and retaining walls.

Advantages of the precast concrete pile

- High load-bearing capacity

- Anticorrosive construction

- Safe and fast sturdy pile joints

- High buckling strength

- Environmentally friendly