FaMe shuttering is a patented modular system for preparing precast concrete molds for walls, beams and columns, including sides, door and window openings, and recesses for HEPAC installations.

FaMe systems includes the patented jaw-type magnets of various types, light aluminum side profiles with or without plywood, as well as other utensils.

Magnets hold the side forms during the casting and vibration processes.

HOW DOES IT WORK?

FaMe shuttering system works with any type of the formwork materials. It is usable on casting tables and beds with steel surface, and in vertical battery molds.

Prepare a precast casting mold of designed size and shape by using FaMe side profiles and shuttering magnets. The system provides quick operation leading to improved efficiency when setting out and breaking down the formwork.

Watch an introduction to the FaMe system

An introduction to the system, the different options it offers, and how it works by Elematic shuttering specialists, sales engineers Paul Görner and Badei Makhmour.

If you got interested, scroll further and book a session with Paul and Badei to find out how the FaMe system will improve your precast production.

The FaMe system consists of:

How to use magnet shuttering in solid wall production?

Watch the video and see how FaMe magnet shuttering system is used in solid wall production in a battery mold. The practical door and window mold, for example, guarantees straigth 90 degree corners and is light and easy to carry and move.

WHAT’S YOUR SHUTTERING CHALLENGE?

Lack of casting surface. Heavy materials.

Amount of waste. Keeping corners straigth.

Do you want to maximize the usage of the casting table surface in your precast wall production? Or does your production efficiency suffer ’cause you always need a crane to lift heavy formwork? Is it the amount of waste that creates a problem? Or perhaps you’ve got challenges with keeping the corners of window and door openings straigth?

If any of these sounds familiar, the FaMe shuttering system might be just the right solution for you.

DOWNLOAD OUR SHUTTERING GUIDE BELOW AND SEE HOW TO SOLVE YOUR CHALLENGES.

WHAT DOES ELEMATIC FAME OFFER?

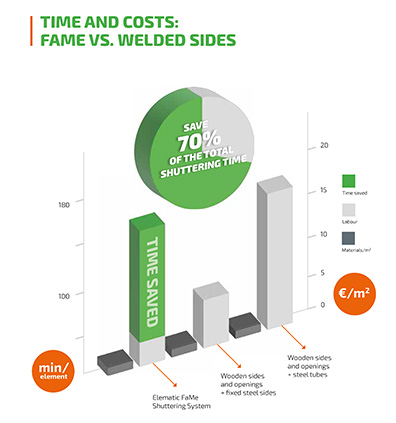

FaMe will save up to 70% in shuttering time with even triple the efficiency of the precast production.

With FaMe shuttering system you can:

- Produce panels with precise dimensioning

- Make straight 90 degree corners

- Use the same formwork for different panel thicknesses

With FaMe magnet shuttering system, you will:

- Save money, time and space

- Increase profit

- Increase productivity

- Increase panel quality

- Accelerate production speed

- Cut down on work phases

- Ensure safety

- Reduce waste

Read more

-

Have you calculated ROI for your shuttering system?

When choosing a shuttering system, it is typical to look at the initial investment and pay less attention to future…

-

How FaMe magnet shuttering system improves your precast wall production?

Would you like to make your wall production cost-efficient and safe? Elematic’s FaMe magnet shuttering system…