Precast is a sustainable choice

Precast concrete offers significant benefits in terms of sustainable construction. The concrete’s local natural and recycled components, low water/cement ratio, good insulation and thermal properties, energy efficiency, durability, and recyclability help minimize the carbon and water footprint while delivering excellent living and working conditions.

BIBM (Federation of the European Precast Concrete Industry), defines sustainability in the precast industry as a development that meets the needs of the present without compromising future generations’ ability to meet their own needs.

A sustainable approach in precast brings lasting environmental, social, and economic benefits to society. Precast is a fast, standardized construction method, which, for instance, can help rapidly developing countries to boost affordable housing. Precast uses little water during production and hardly any at the construction site. Quick erection minimizes noise and pollution impact on the neighbourhood. At the same time, the site remains clean and in order because precast elements are ready to install and storage need is negligible.

Sustainability begins from raw materials for precast concrete

Concrete has a relatively low embodied energy value, unlike some other highly processed materials. 70% of concrete are sand and gravel that are mostly local natural materials and require minimal chemical treatment. Local means also shorter and less polluting transportation compared to imported materials.

An excellent example of the precast’s efficient raw material use is pre-stressed hollow core slabs , which need up to 45 % less concrete and 30 % less steel than a plain cast-in-situ reinforced slab. Pre-stressed concrete also enables longer spans and offers more architectural and structural freedom in design.

Read more about concrete-

What you manufacture determines the right type of concrete

Before designing the concrete mix, you must define the requirements of the concrete based on the specific precast…

-

The ABCs of concrete production

What are the main focus points in precast concrete production and the concrete mix? The products that you are…

Serious efforts on reducing the carbon footprint of cement

As we know, cement is the most significant source of CO2 emissions in concrete. The precast industry is continuously looking to reduce the already low amount of cement in precast and replace it with other ingredients.

WHITE PAPER: Reducing emissions in concrete production. Showcasing how precast solutions can lower carbon footprints and enhance sustainability in construction

Concrete production significantly contributes to global CO2 emissions (an estimated 8 percent of global CO2 emissions). Therefore, reducing the emissions generated by concrete production is imperative. Sustainable methods of concrete production must replace traditional energy-intensive processes.

Precast concrete, created in controlled factory settings, offers significant environmental benefits for concrete production, including reduced CO2 emissions. Adopting modern technology can further improve sustainability within precast concrete production.

This white paper presents a study by Sweco, engineering and architecture consultants, which compares the emissions of precast concrete manufactured in various production lines. It sheds light on how modern precast concrete technology can reduce carbon dioxide emissions in hollow core production by a staggering 35% compared to conventional solutions.

Precast enables recycling at every stage of its life cycle

The volume of recycled raw ingredients in precast grows steadily worldwide. Technologies of utilizing recycled steel, concrete or its substitutes, recycled construction and demolition waste in a concrete mixture are evolving.

Modern concrete plants built closed-loop recycling systems for wastewater and concrete , enhancing manufacturing efficiency and reducing environmental impact.

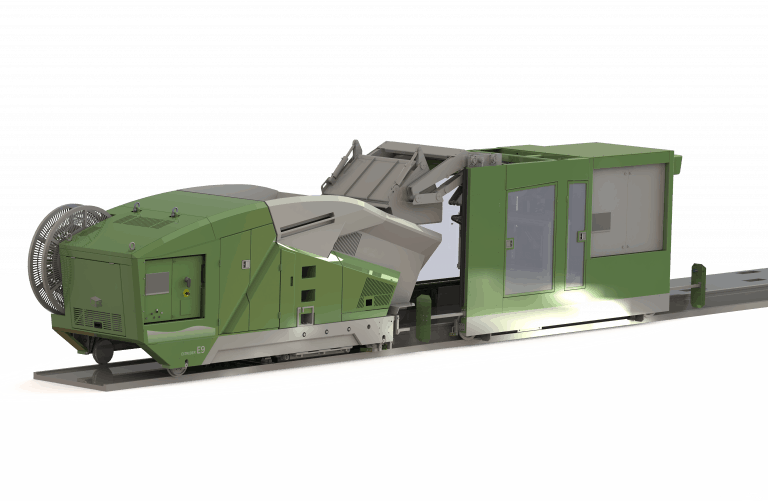

Elematic offers many ways to decrease the use of concrete in precast production. One of the latest innovations is a recycling system for Extruder – Modifier operation process.

Read moreRead more about sustainability in precast production

-

How to save cement in hollow-core slab production?

Have you pondered how to increase the productivity of your precast plant cost-efficiently? How to save cement and…

-

Closed material loop is a responsible way to save resources in precast manufacturing

Becoming a frontrunner in closed material loops in precast factories has not been fast nor easy. VBI started…

Precast is an energy-efficient solution in construction

The energy efficiency of buildings is one of the major aspects of sustainable property development. Due to excellent insulation and thermal properties, precast products are applicable in all climates. Heavy-weight concrete buildings accumulate energy and minimize power demand.

Insulated sandwich walls reduce energy consumption for both cooling and heating. The hollow-core slabs, then, are a perfect sight for the cooling system, which uses up to 50 per cent less energy than air conditioning.

Read more about sandwich wall Read more about hollow coreThe durability of precast is a significant sustainable value

Concrete structures have a long service life and low need for maintenance and repair, providing significant sustainable value. While climate change and worsening natural disasters challenge construction materials to withstand heavy rainfall, wind-blown debris or fire, concrete demonstrates high fire resistance and moisture tolerance. Precast also resists high compressive forces and is successfully applied in seismically active regions. Precast concrete is easier and cheaper to repair after damage than other building methods.

Demand for environmental certification of buildings is growing

Growing awareness about the importance of environmental issues reflects in increasing popularity of environmental certification of buildings, which, in turn, becomes a competitive advantage in real estate.

Different green building rating schemes like LEED USA, BREEAM, GRIHA, BEAM Plus, Green Mark and CASBEE have been introduced in different countries and applied internationally.

Precast concrete is a perfect way to low-carbon production, low-impact design, minimizing the energy demands created by a building while utilizing low carbon technologies.