VR models offer an immersive view of precast plants

In a few weeks, Elematic will unveil a VR model of a hollow-core factory, allowing customers to visualise what it’s like to be in the centre of it all. Petteri Laitinen, Vice President of Projects and Services, tells us more about this exciting development.

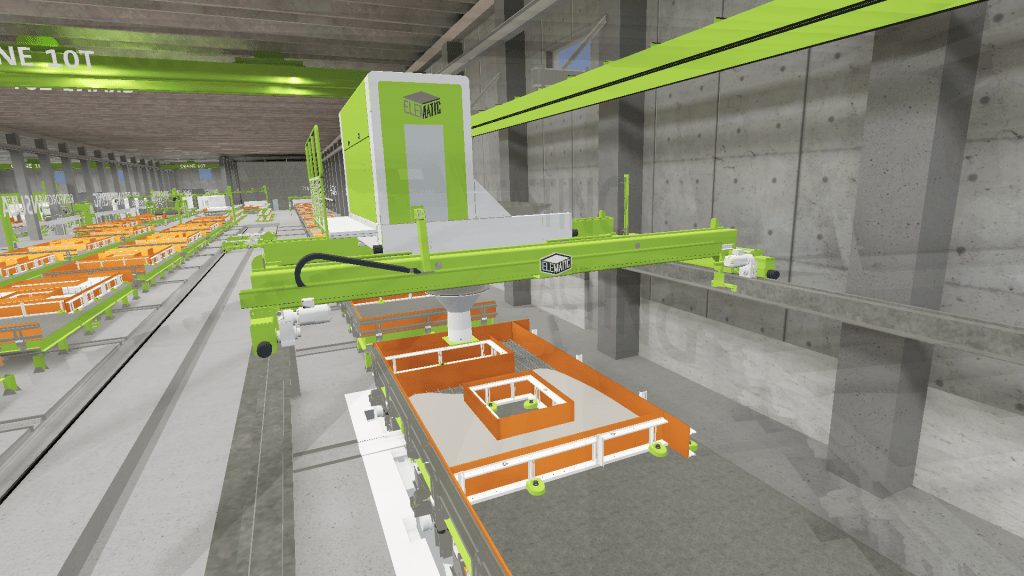

Imagine being able to step into a virtual model to see how the factory is built. Imagine moving around the space, just by moving your computer mouse or your fingers on a mobile device and really seeing how it’s going to looks like. This is what we want to offer: how with modern technology it is possible to visualise how the plans will function in reality.

Virtual models put people in the middle of the factory and give them a concrete idea about how the machines, space and the different functions and operations all come together. It is not always easy to understand from a 2D-line drawing what is required of the building where the production line will be built or how much space is actually needed for everything to really fit in and how it really will feel when working in that environment; but from a 3D model, it is easier to grasp this. VR takes the guesswork out; and by doing that, it also allows customers to avoid costly mistakes.

For instance, let’s say you want to build a precast plant from scratch. When putting together the layout design, we have to make sure that there’s enough space for production to happen, for storing the finished products, for materials to move from place to place, for workers to move among the machinery while ensuring their safety, among other things. We need to ponder if the building ceiling is high enough to accommodate machinery above casting beds, such as overhead cranes, for example. Using a virtual model of the proposed layout makes it easier to see why a building with a 7m-high ceiling is needed. Or should you decide to expand your existing production line, will the new machines fit in the space available?

Of course, 3D models have been around for a while, but they have usually been used in design software that require very powerful computers to run them smoothly. Now we can use similar technology to what the gaming industry – which is highly evolved in Finland – is using, making the model itself smaller so that smartphones and tablets can run them.

One of the reasons Elematic turned to this technology is its ease of use. Our next step is to use VR as part of our offers. Then, in the future, plant layout designers can use VR modelling to make sure that there is a place for every machine and that every machine is in its place. Or when an installation supervisor comes to your site, the VR model can be used to explain to the factory crew how the installation will progress.

Elematic has been on the frontline of digitalisation of the construction industry and I believe that VR models are the next step we need to take.

Petteri Laitinen