The ABCs of concrete production

What are the main focus points in precast concrete production and the concrete mix? The products that you are manufacturing determine the appropriate mix design, strength, hardening process, workability, and durability of the concrete. By paying attention to these aspects, you can ensure consistent quality, effective production, and low costs for your products.

The production of concrete is continuous precision work. A successful precast operation demands a proper understanding and management of concrete technology.

Since concrete is the primary raw material for precast products and structures, it has an important influence on quality, production effectiveness and costs. The components of a concrete mix must always be chosen according to the qualities required of the fresh and/or hardened concrete.

Concrete is the primary cost factor in most product groups. Other factors include the complexity of the production process, the amount of labor needed and eventual labor costs.

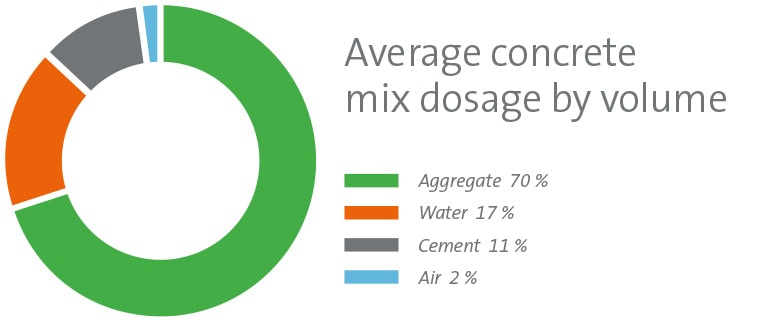

A good concrete mix is essential, and it must be optimized continuously. In order to make strong and durable products, the aggregate volume should be maximized and the volumes of cement and water minimized.

Making the concrete mix starts with an evaluation of the local facilities and the available raw materials, both of which have a great impact on your final product and the structural and aesthetic quality of concrete. The mix design should be fully tested in pre-production.

The concrete mix and its curing method strongly affect the speed of the production cycle. The hardening time can vary between 5–20 hours.

Cement quality is critical to the production cycle. The best results are achieved with cements that are designed especially for the precast industry. The availability of different cement types varies across different markets.

Environmental matters are receiving increased attention, and it is very important to calculate the costs over the entire lifecycle of a building or structure.

Aggregate quality matters

Aggregates are the main component of concrete, making up over 70 per cent of concrete by volume and 80 per cent by weight. You could say that aggregates provide the frame, and cement acts as the glue between the aggregate particles.

Aggregates mostly come from natural sources, which means that there can be significant variation in the type and quality of aggregates – even if they are from the same source. The variation is larger than with cement and other components, so quality control at the factory lab should emphasize aggregates.

Since the correct selection of aggregates can strongly affect production efficiency, continuous monitoring of aggregate properties is advisable; grading tolerances are usually too broad to guarantee constant concrete quality.

Fines are also essential for the properties of fresh and hardened concrete. Fines act as a lubricant in the fresh concrete: they ensure workability and water retention. They reduce the risk of mixture separation during installation and make compaction easier. They also reduce the air content. However, excessive amounts of fines can lead to stickiness. They can also lead to greater shrinkage and creep tendency because of the increased water content.

Cement affects the costs

Cement covers only about 11 per cent of an average concrete mix by volume, yet it is the primary cost in the mix.

The cement qualities available in different markets vary. Some markets have different cement types available for different applications. The cement types used in the precast industry are mostly CEM I, CEM II and CEM III.

The cement type used has a direct impact on the concrete’s properties, such as water demand, setting time and strength development.

Cement factories generally provide quality information about their cements, including strength at different ages, nominal area, color, and the amount of blended materials. Early strength is often the main requirement in precast production.

Drinking water can be used to make concrete. Other types like wash water, ground water, or industrial process water must be tested, and waste water is a definite no-go.

Admixtures and additives bring out desired properties

Concrete admixtures are liquids or powders that are added to the concrete in small quantities during mixing. Make your selection carefully with the help of admixture producers, and check the impact of the materials by doing proper pretesting.

Plasticizers are the most commonly used admixtures. They are used either to increase the compressive strength or to produce a more flowing concrete with the same amount of water.

Concrete additives are fine granular materials that are used to enhance or obtain specific properties of fresh and/or hardened concrete.

Inorganic additives include nearly inert additives (such as color pigments) and latent hydraulic additives (such as fly ash).

The perfect concrete mix design

Quality control at the factory should emphasize aggregates.

How do you know which raw materials to choose and what their interactive proportioning should be? The appropriate mix design depends on the final product.

When starting your mix design, consider the desired properties of your product, the quality of your raw materials, as well as your production process and structural requirements. What durability or strength is demanded of the concrete at different ages? What is your production cycle and what compaction or curing methods are you using? What mixing and batching equipment do you have available, and what is the right mixing intensity and mixing time? How is the concrete transported inside the factory? What is the required lifetime and durability of your concrete? Aesthetic requirements will determine the surface treatments of your product and also affect the costs.

Properties of fresh and hard concrete

The consistency of fresh concrete defines its behavior during mixing, handling, delivery, casting, and compaction as well as surface smoothing. It also dictates the workability of fresh concrete, and workability requirements depend on the type of product manufactured and the production method used.

You should aim at good cohesion, a low risk of segregation and good surface smoothening or finishing properties. Try to reach cost-effective handling, pouring or placing, and finishing of the fresh concrete. You can reach maximum plasticity or flowability by using superplasticizers. In hot climates, you can extend workability by using retardation. In cold climates, you may want to accelerate the setting and hardening process.

Hardened concrete has several important properties that need to be considered: compressive strength in different ages, tensile strength, deformation, water tightness, frost resistance, corrosion, abrasion resistance, and density. All these properties depend on successful compaction.

Download full book “Basic concrete technology for the precast industry”

This book goes through all basics of concrete technology that a precast producer needs to know: raw materials, principles of mix design, concrete production, properties of hardened concrete, requirements for different concrete types as well as special aspects in concrete production and products.

Download your free copy now!

The main properties for precast concrete

- Cost-effective mix design

- Strength determined by the mix design

- Fast and controlled hardening, the importance of early strength

- Appropriate workability (dictated by the casting method)

- Good durability (dictated by the design requirements)

Share of concrete costs in total direct production costs

| Product group: | Concrete cost as % of direct costs |

|---|---|

| Paving and blocks: | 70–80 |

| Hollow-core slab: | 40–50 |

| Columns and beams: | 20–40 |

| Solid walls: | 30–40 |

| Sandwich façades: | 20–30 |

Why concrete technology is important in the precast business

The concrete mix strongly affects the aesthetics – the surface – of the product.

The mix also determines the product’s structural quality (load bearing capacity).

Concrete is the primary cost factor in most precast products.

The concrete mix and its curing process determine the length of the production cycle.

Environmental matters are of increasing importance, which means that the use of concrete as a building material must be effective.

Different factors affect the consistency and compactability of the concrete mix

· Water increases flowability and reduces strength.

· Binders increase the need for water.

· Round aggregate shapes improve compactability and reduce tensile strength.

· An optimal grading curve improves compactability.

· Plasticizers reduce water demand.

· An increase in temperature – or a delay in casting – reduces compactability.