Tampere Deck and Arena. An exceptional precast building project on top of railway tracks

Rising in the heart of Tampere city, Finland, the Deck and Arena complex is truly a feat of engineering. The technically challenging construction project represents something new and exceptional in international comparison. It has no known equivalents in either Europe or the USA.

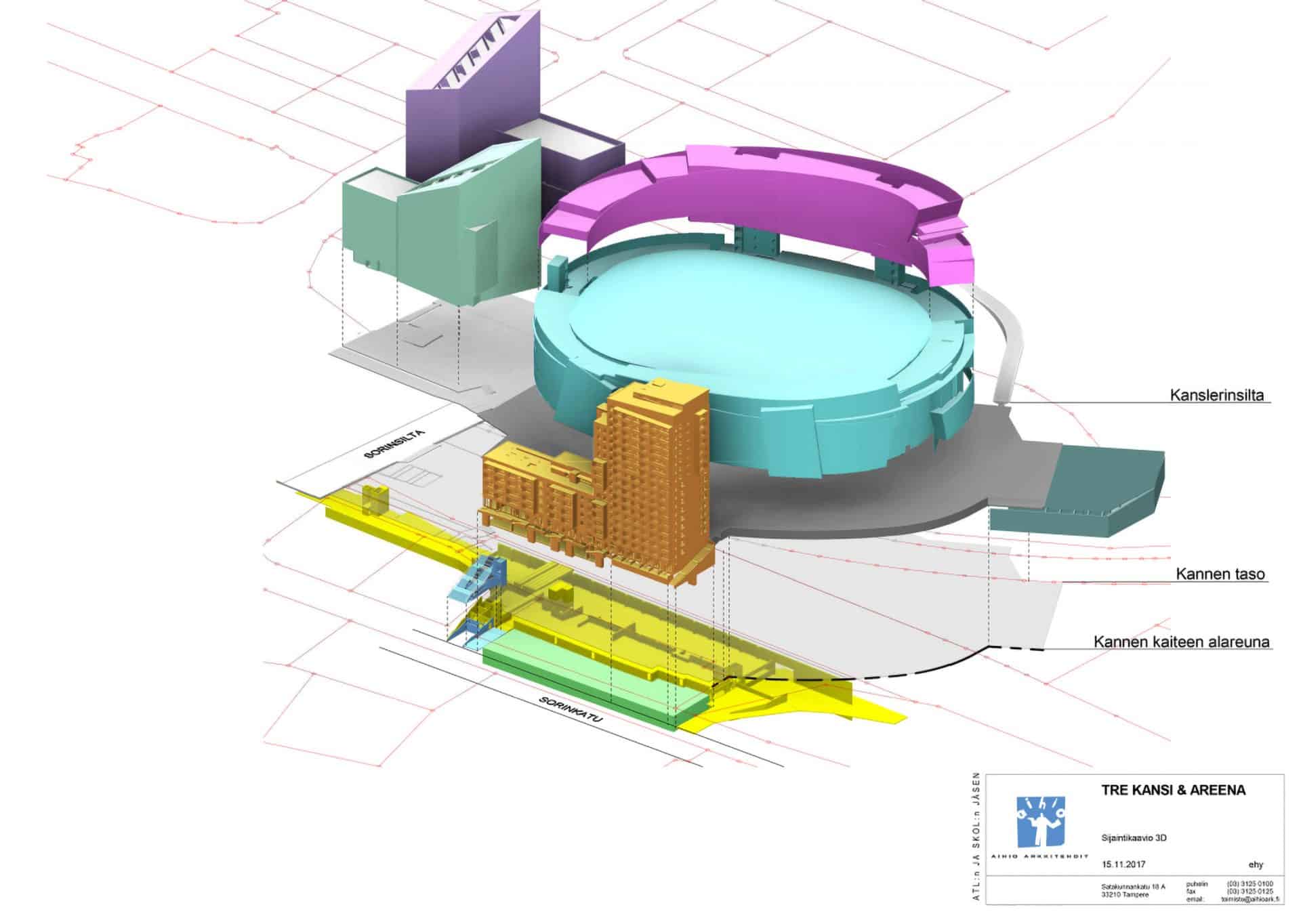

From 2017, a unique construction project has been underway in Tampere city, Finland. The Deck and Arena complex will create a brand-new neighborhood, a city inside a city, right next to the local railway station. The Deck and Arena will be home to the city’s tallest residential buildings with over a thousand apartments, along with Finland’s largest sports and event arena, the adjoining casino, hotel, and restaurants, and other entertainment spots.

What is particularly interesting about the construction project is the fact that the central deck is built on top of railway tracks. The deck supported by pillars is about nine meters above the ground, and the multipurpose arena and two tower blocks are built on top of the deck.

The first phase of the project – the South Deck, arena, and two towers – is scheduled for completion in 2022. The whole project (including three more tower blocks) will be completed in 2024. The project is designed by Studio Daniel Libeskind.

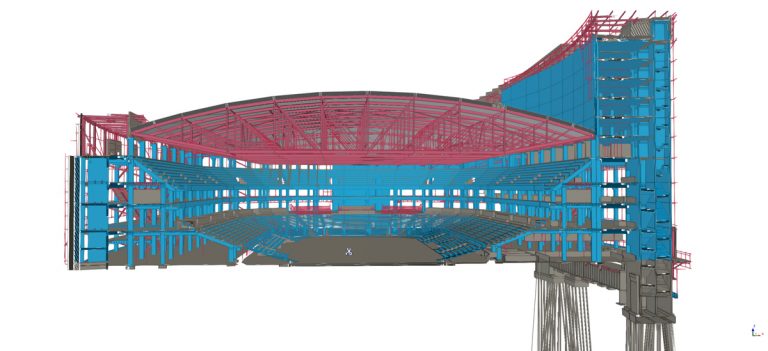

The native model of the structural designer, cross-section

• The 4-5 floors high arena is set up entirely on the deck. The top floor is the ventilation room.

• The 5-6 floors high hotel rises from the arena.

• There are 4 contraction joint segments in the arena.

• Frame system:

– 6 reinforcing vertical shafts,

– Precast concrete frame, which is a pillar-beam ring. Hollow core slabs used in the arena, and half slabs at the hotel.

A very challenging project

Finland’s leading project management contractor, SRV, is developing and constructing the Deck and Arena complex. Production Manager Jouni Hämäläinen says that they have faced many challenges along the way. “For instance, the design had to be carried out on the terms of railway geometry, so the load bearing structures placed in the ground are not in optimal places.”

The complex has a precast concrete frame. Precast was chosen as the best solution in terms of total economy. According to Jouni Hämäläinen, moving massive loads to foundations with concrete structures was the only possible option.

The major construction challenge was to build the arena and the tower blocks on a bendy deck structure.

“The structures designed on top of the flexible deck have required some special solutions, particularly with regard to joints. Vibration caused by train traffic has been taken into account by vibration absorbers that separate the deck from the structures above.”

About 150 trains pass the construction site daily from underneath. During the project, train traffic or other traffic could not be interrupted. What is more, site logistics is challenging on a city center plot with only a minimal amount of land next to the buildings.

“Lots of materials have been delivered to contractors every day, but there is little room for trucks to unload, so concrete elements have been installed directly from the trucks delivering them”, Hämäläinen describes.

SRV

- Developer and innovator in the construction industry.

- Established in 1987. Listed on the Helsinki Stock Exchange.

- Operates in growth centres in Finland and Russia.

- In 2020, the revenue totalled EUR 975.5 million. In addition to about 1,000 SRV employees, the company employs a network of around 4,200 subcontractors.

Exceptional joint engineering

Ramboll Finland is in charge of the structural engineering of the project and also the main structural designer.

“The entire structural complex is very demanding and unique. It has no equivalents – that we at least know of – in Finland, Europe, or the USA. We have had to design some exceptional structures, such as the deck structure, says Heidi Merikukka, Project Manager, Ramboll.

The structural system of the deck consists of hundreds of concrete columns, over 300 precast concrete crossbeams, and cast-in-situ support beams. The load bearing slab of the deck is strongly reinforced and about 40 centimeters thick. Buildings on top of the railway line have made the bearing distances in the founding area very long. The arena and other buildings on top of the deck transmit large vertical loads to the deck, so the deck structures must be massive.

“The structural technical specialty of the project was the construction of the above buildings on top of the flexible deck structures. And this also had a large impact on the design of the joint at the lower end of the column and deck connection. Due to the vibration noise caused by train traffic, the frame structures of the Arena and tower building had to be separated by dampers at the deck level. Because of vibration and the bending deck structures, the joint type between precast concrete columns and the deck was a completely unique and novel solution in Finland”, Merikukka says.

The 17-storey buildings are founded on separate prefabricated raft structures. The weight of one precast concrete beam was about 100 tons (17 pieces of precast concrete beams per raft) and slab thickness of the rafts was 1,2 meters. The column loads transmitted from the tower blocks have peaked at 20 meganewtons. They are directed through special structures to drill piles that are drilled to a depth of 30 meters.

“Because of vibration and the bending deck structures, the joint type between precast concrete columns and the deck was a completely unique and novel solution in Finland.”

RAMBOLL FINLAND

- A business unit of the global engineering, architecture and consultancy company Ramboll Group A/S founded in Denmark in 1945.

- The foundation-owned company employs 16,500 professionals from different fields globally. In Finland, it operates nationwide with 2,500 experts.

- Ramboll’s turnover in Finland is EUR 240 million.

Arena and hotel: a demanding mix

The precast concrete frame for the arena and hotel complex was designed by Consolis Parma. According to Design Manager Pasi Salmela, the combination demands a lot from noise absorption.

“The lower floors of the hotel are also premises of the arena, so the hotel is constructed on top of the arena. Some hotel rooms have balconies with a grandstand view of the arena. This is a specialty of its own. We had to prevent the transfer of concert noise from the multipurpose arena to the hotel rooms, which was exceptionally challenging.”

“We used noise absorbers in the joints connecting the arena and the hotel in order to damp the frame noise coming from the arena”, Salmela says.

One of the most successful details concerning elemental technology were the auditorium structures. The supporting beams in the auditorium are located on pillar lines, and the auditorium rows consist of L- and T-shaped planks. The planks were made with steel molds as industrial products. This was possible since the element supplier was asked to come up with ideas and solutions early on in the project.

“The plank solution and the reinforcement of the frame were both developed during the bidding phase”, Salmela says.

For the reinforcement of the frame, he gives credit to the strength calculators of Ramboll.

“The most difficult part of all was the reinforcement of the building. The movements of the cast in-situ deck cause distribution of forces. Taking them into account in the reinforcement calculation was critical. Ramboll did a great job with that, and the element frame could be worked out.”

Salmela is proud for taking part in such an exceptional project.

“When I finally go and see my first ice hockey game at the Arena, I will be most proud of the fact that we have been able to bring prefabricated elements to this technically demanding project that contains so many well thought out details.”

Heidi Merikukka is also proud for being involved in a project that is quite unique in its entirety.

“There are many technically challenging structural solutions there that we haven’t seen in other construction projects in Finland or elsewhere. The Deck and Arena is a wonderful landmark for Tampere, and, of course, for Finnish ice hockey.”

“We had to prevent the transfer of concert noise from the multipurpose arena to the hotel rooms, which was exceptionally challenging.”

CONSOLIS PARMA

- Parma Oy is Finland’s largest manufacturer of precast concrete elements.

- The company is a partner of construction professionals and a reliable element supplier for single-family house builders.

- Parma Oy employs more than 900 people and is a part of the International Consolis Group.

A wide range of precast concrete elements

- Consolis Parma has supplied approximately 7,000 elements to the project.

- The range includes hollow core slabs and thin-shell slabs, partition walls, façade walls, pillars, beams, auditorium beams, auditorium planks, and solid tiles.

- Six factories have been involved in the production from May 2019 to September 2020

Scope of the Tampere Deck and Arena project

- South deck: 19,800 GSM2

- Arena: 40,800 GSM2

- Hotel: 10,800 GSM2

- Training hall: 2,700 GSM2

- Building 1: 13,100 GSM2

- Building 2: 12,300 GSM2

- Parking facility: 14,700 GSM2

- Total scope: approx. 115 500 GSM2

The Tampere Deck and Arena will serve as the main venue of the 2022 IIHF Ice Hockey World Championship in Finland. It will also be the new home for the cities two top-league clubs, Tappara and Ilves.