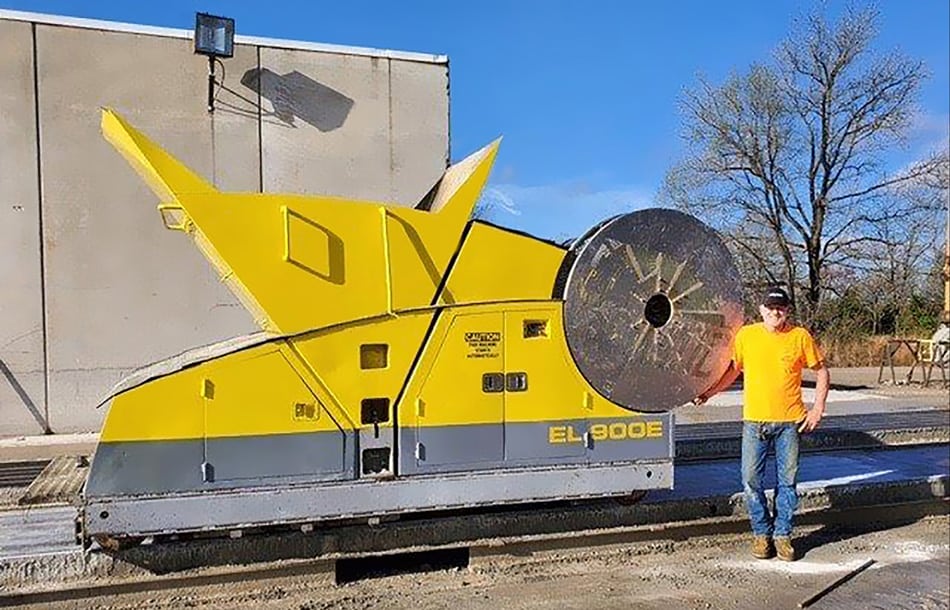

Reliable production since 2000 with Elematic EL 900E

Mid South Prestress (MSP) is the largest producer of hollow core slabs in the mid-southern United States. MSP does everything from design to delivery and installation. MSP is still successfully operating with the same Elematic machines that the company bought 20 years ago. For example, Extruder EL 900E is running smoothly and maintained with care regularly.

Even though the companies were young at the beginning of the millennium, both Mid South Prestress and Elematic inc. have plenty of experience in precast manufacturing. Production Manager Moe Bertelsmann has been involved in MSP’s production ever since the company was founded in 2000. Since then, production has been expanded to four lines and products are sold widely in the areas around Nashville.

“We ended up working with Elematic based on the research of our founder John Towell that their machines had reliable mechanical parts. Production got off to a good start and sales were good, so we expanded the plant soon after it was established. We use all the beds when we make elements for different deliveries at the same time,“ Bertelsmann says.

“From early on, I knew it was important to build a strong support system. MSP chose us as their technology partner based on our promise to stay by their side and help make them successful. After 21 years, we are still by their side,” General Manager Matt Cherba from Elematic Inc. points out.

Just like hot rods

In the past two decades, Bertelsmann has learned to know both Elematic and their machines thoroughly. Every few years, he checks the extruder technology carefully and even repaints the machines.

“When you take care of machines, they take care of you. Just like with cars, regular maintenance is important. These machines are my hot rods,” Bertelsmann admits.

Bertelsmann keeps the most common wear parts in stock. That way he can change the parts as soon as needed and ensure that operations keep running as planned.

Bertelsmann is very happy with the cooperation with Elematic. Communication works well, and he has always received support when needed.

“Sometimes I have called Matt on a Sunday night, and Matt has always called back, latest after 15 minutes. And the spare parts always come as agreed.”

Many more years to come

According to Cherba, Elematic offers many modern technology and the company is constantly developing and looking for new solutions. However, its commitment to support current operations remains top priority.

Technology is moving forward and at some point, components will simply no longer be available. When Bertelsmann was notified that manufacturing of a power unit used in MSP will end, he ordered a new one. Just in case.

“Everything works as it should, that’s great. The machines have paid for themselves a long time ago. Now what they produce is profit for us. We will probably use them for another ten years. Maybe before I retire, I can buy new Elematic machines,” Bertelsmann laughs.

Mid South Prestress

- Founded in 2000

- Produces hollow core slabs, beams and columns from planning to erection

- Four precasting lines at 520 feet

- Elematic machinery: extruder, 5 nozzles, 3 power units and span saws.