How to choose the best wall connection?

A Concrete Issues reader requested to learn more about wall connections in precast buildings. We asked Assistant Vice President for Design Nishant Sharma to introduce us to the topic.

The first thing that Sharma and his structural engineer colleagues in the Elematic Design Services team consider when designing connections for precast buildings, is how different load types will affect the structure.

Whether we are talking about horizontal or vertical connections, they will be affected by the axial load, moment, and shear force. Crack limitation and changing temperatures are also part of the equation.

“We look at how these loads are expected to impact the structure and that dictates the requirements of the connections,” Sharma explains.

Dry or wet joint

When talking about how to connect elements, we distinguish between dry and wet joints.

Wet jointing means connecting elements with wet concrete or grout. This method is usually used for precast projects in seismic areas, Sharma says.

“An example of a wet joint is a wall-to-wall horizontal connection where the rebars are going from the lower precast element into a coupler in the upper precast element. When the wall is lowered down by the crane, the rebar automatically inserts inside the coupler, and then the grouting process is done at the site.”

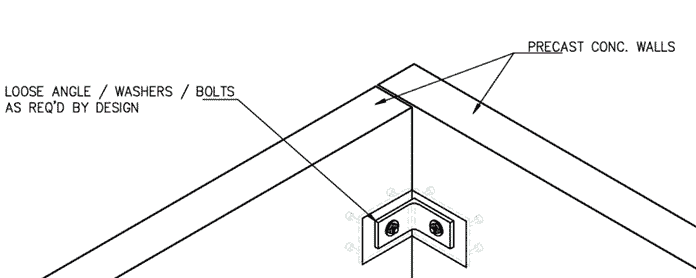

A dry joint means that two wall panels are fastened to each other, typically with steel plates bolted or welded at the site. As the name suggests, it doesn’t require any concreting at the site. Concrete has good fire resistance, but steel tends to melt quickly, so dry connections will require suitable fireproofing treatments.

“Whatever type of joint we decide to use for a project, each joint will be experiencing all the categories of forces, and the engineer has to ensure that the joint can withstand them.”

Crucial horizontal connections

Wall panels are connected in two directions: Horizontally connecting precast panels placed on top of each other, typically different stories in a building. They are designed to carry the load traveling from the top down the wall elements resting on top of each other.

Vertical connections on the other hand connect the elements on the side edges.

They are both important, but structural engineers pay particular attention to the horizontal joints.

“If a horizontal joint fails, the element above will naturally collapse, which will lead to the collapse of the element above, and so on. Progressively, the entire structure will collapse,” Sharma says.

He compares the importance of horizontal joints to any vertical element in a structure, such as columns and walls. Horizontal elements, such as beams and floors are naturally important too, but they can typically be remedied locally in case of failure.

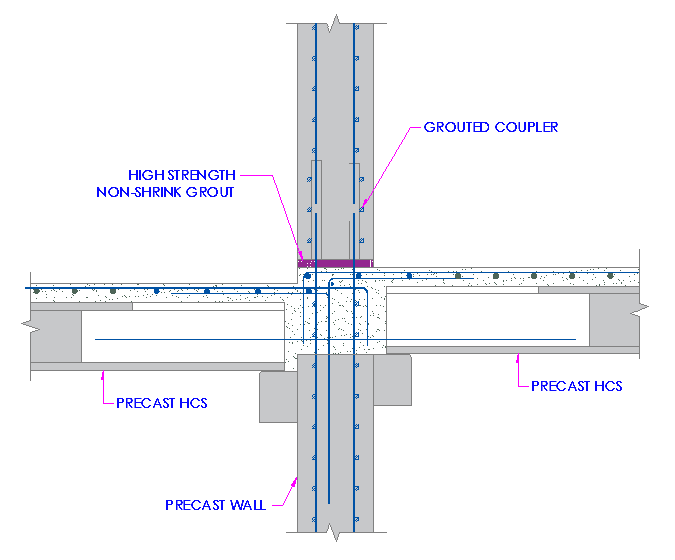

High-rise horizontal wet connection

High-rise structures in mid to high-seismic zone call for strong connections. Due to high compression induced at the ends of the wall, double layers of dowels (projected bars) are required to continue from the bottom wall to the top wall.

The wet on-site concreting is not only done inside the wall-to-wall joint but also continues across mesh reinforcement across the entire floor, forming the diaphragm. All the different precast elements – walls, columns, beams, and slabs – have projections of rebar bent into the diaphragm before the topping is cast.

The diaphragm acts as a tying element, ensuring that all the precast elements of that floor will act as a single unit when exposed to lateral forces generated by for example an earthquake or wind. Structural engineers call this emulative behavior, as it emulates the behavior of an equivalent cast-in-situ structure.

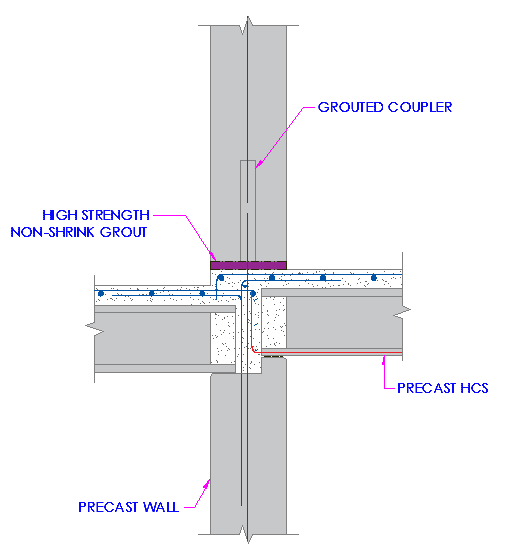

Low-rise horizontal wet connection

As the gravity load is less, the load transfer does not require two layers of dowel bars projected from the below wall to the one above. With one layer of middle dowels, hollow core slabs can rest on the top surface of the wall and hence, it does not need any ledge.

Strong and practical vertical connections

Generally speaking, vertical joints come in two versions: A seismic- and wind-resistant joint that emulates the behavior of a single wall cast on-site and a joint connecting two separate walls.

Sharma and the rest of the Elematic Design Team are based in India, a country with high seismic activity. While keeping the risk of earthquakes in mind, Sharma also reminds us that constructability is a main concern.

“We have to bear in mind the sequence of construction to ensure that the vertical joint in such type of joint where the emulative behavior is trying to be achieved, should not be challenging by the site team to be addressed.”

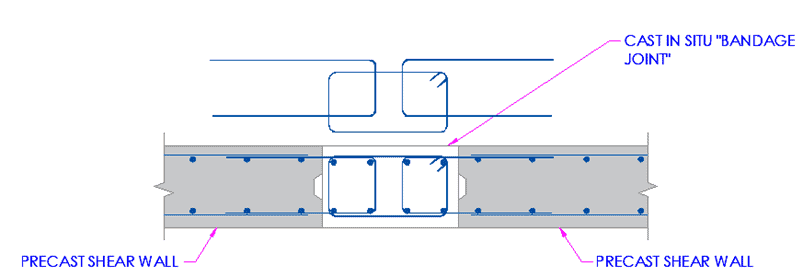

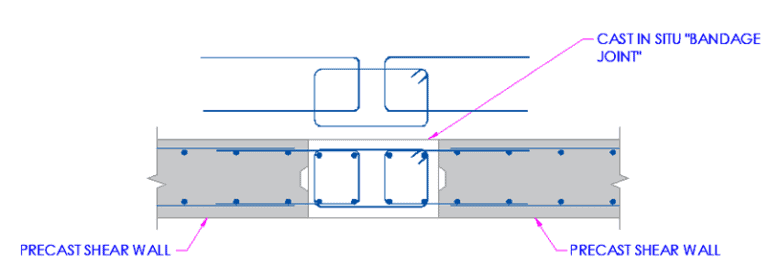

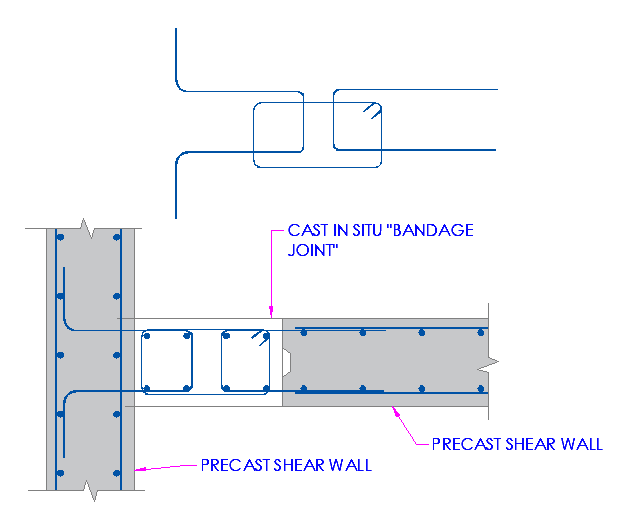

Seismic vertical wet connection

This vertical connection aims to make the two walls behave as if they were cast as a single wall. Inverted U bars are coming out of either end of the wall and there are stirrups inside.

This is easy to erect: You have the side double bars, and then you put shuttering on each side and pour concrete from the top (image is plan view).

Seismic T junction wet connection

The same philosophy is utilized for T junctions. An additional stirrup goes around all the vertical columns, achieving emulative behavior as well.

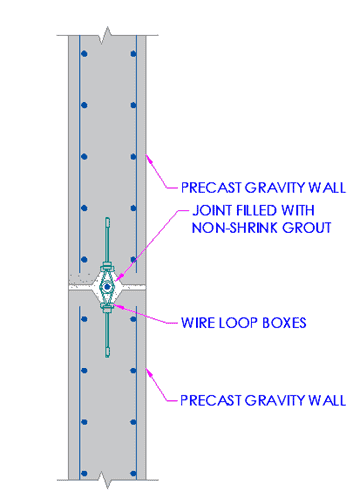

Non-seismic vertical wet connection

In a situation where the only critical force transfer is the shear force, we don’t want moment to be transferred from one wall to the other. Here, emulative behavior is not required.

No extra on-site activity of shuttering and concreting is necessary. Instead, wire loop connections are used: a system utilizing overlapping wire loops, a single toggle bar, and grout.

Jointing materials

- Concrete

- Coupler

- Grout

- Reinforcement

- Wire loop boxes

- Structural steel (for dry connections)

Elematic Design Services

The team consists of specialists in structural design of precast buildings.

They provide developers, construction companies, and precast manufacturers with technical consultancy and support from building concept design to detailed engineering and execution.

Related services

Want to know more? Please contact us!

or