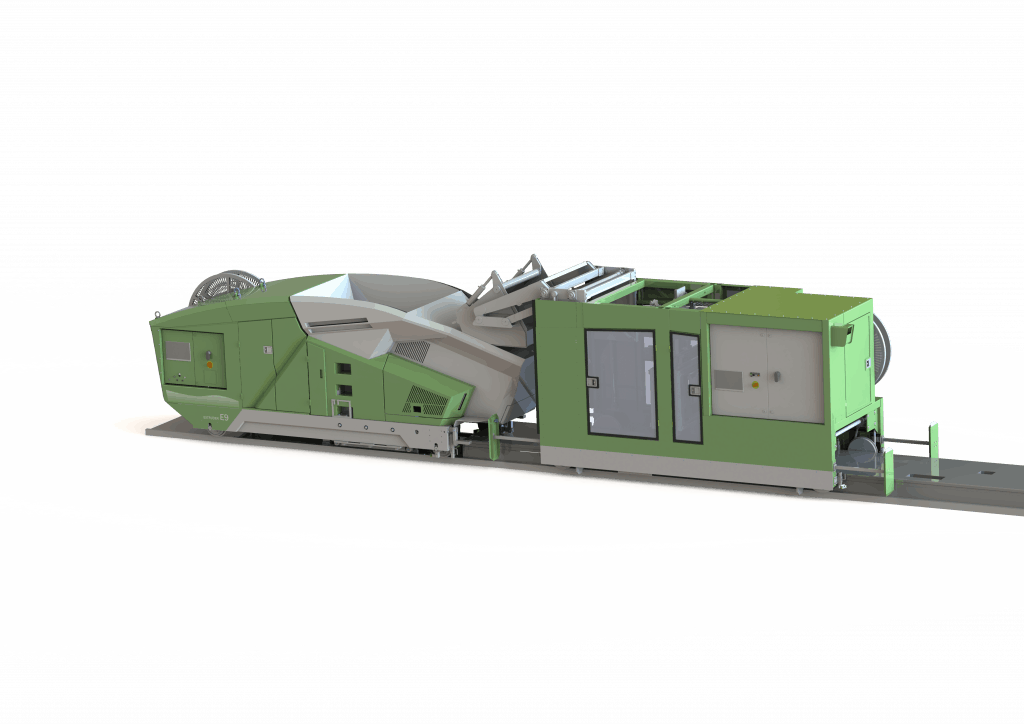

Modifier E9-2019 takes accuracy to the next level

The Modifier E9-1200e is used for digging openings and recesses and drilling water holes on fresh concrete slabs on a hollow-core production line. It can also plot cutting lines, openings and texts. It is intended for automatic operation, but can also be operated in semi-automatic and manual mode.

By doing modifications straight onto unhardened slabs, the modifier saves considerable time by eliminating the need for manual marking of cutting lines or making openings for lifting loop installations and through holes. Reducing the need for manual work frees two to four workers, eliminates mistakes and improves safety on the shop floor.

The Modifier E9-2019 uses wireless technology to transfer bed plans to its FloorMES machine control system. Location information is acquired from the laser positioning system. The laser uses a mirror at the end of the bed to measure distance.

Like all Elematic machinery, safety features are built-in. The Modifier E9 is fitted with a safety buffer on both ends, including light sensors, which protect the area in the middle of buffers. In addition to these, there are also ultrasonic sensors, which add to safety, but also make it possible to pause the operation when i.e. getting close to the extruder. The operation can be resumed, when the obstacle moves away.

Because the Modifier E9-1200m uses no water in digging, concrete removed from openings can be recycled back to the extruder. When used with Elematic’s new Extruder, the Modifier helps decrease concrete consumption in the hollow-core slab production, thus helping meet your sustainability goals.

Do you have questions? Please contact us!

or