Small changes to the shuttering system can lead to big results

Are you having problems with precast mold preparation? Here are some tips that have proven useful for many — changing the parts of your shuttering system can have a significant effect. For example, when you start using aluminum profiles, you will notice that the speed of installing and removing side forms saves a lot of time

When you replace steel side forms with aluminum, you avoid many bottlenecks in production. Aluminum profiles are considerably lighter than steel and can be lifted without cranes. This also ensures work safety.

“Our typical aluminum profiles weigh 4 to 6 kgs per meter, and our most common magnets are about 4,5 kilos a piece. Aluminum is also much more long-lasting than wood, so choosing aluminum will lead to significant savings over time”, says Badei Makhmour, Sales Engineer at Elematic.

Is your working space narrow? Try special magnets

When space is tight, the surface area of casting tables needs to be utilized as efficiently as possible. This can be achieved by using magnets that fit in small spaces and have more than one jaw. When more than one side of a magnet can be used at the same time, you will save space, time, and money.

“One factory was interested in utilizing the table surface area to the maximum in their wall production. They used wide magnets and wooden side forms with plywood. The problem was solved with a four-sided magnet in the middle and aluminum profiles on both sides of the magnets. Plywood was attached to the aluminum profile”, Makhmour describes.

The total width of the new system saved more than 200 mm. For the factory, this meant over 2,5 m2 of new casting space on the table, Makhmour says.

The new side form system was only 172 mm wide, plywood included. The new system was 100 mm narrower than the old system, providing over 16 m2 more area for casting on the bed.

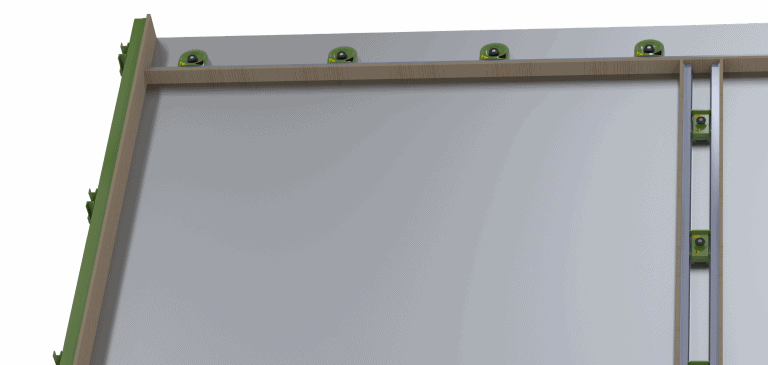

In the Flex system, the profile is attached on top of the magnet, which makes the whole system compact. Molding and demolding are also fast. The system is attached to the table surface by just pushing buttons on the magnets. When removing the system, you simply attach a releasing tool to the magnet and pull the handle to remove it from the mold.

“Instead of concentrating on preparing molds, you concentrate on producing elements. When you don’t need to use wooden side forms, you improve work safety, save money and create less waste”, Makhmour says.

Writer

Badei Makhmour, Sales Engineer, FaMe Magnet Shuttering, Elematic

Let others enjoy this article too!

Keep corners straight with the right equipment

Using wooden forms is time-consuming, and it is hard to keep corners straight. You can solve this problem by using magnets and aluminum profiles which always produce straight panel sides.

“A precaster needed to speed up wall production. The window and door openings were made of wood and plywood, and they had problems keeping the corners in sharp 90-degree angles. The problem was solved with a system consisting of light aluminum profiles, push-button magnets, and corner and locking pieces”, Makhmour says.

The new system is easy to both mold and demold. To remove the mold, you just remove the magnets by using a releasing tool, loosen the T-slot bolts and remove the locking pieces. Adjusting locking pieces will give some freedom with panel size changes.

Leverage the expertise of your shuttering system supplier

Some shuttering systems can be ordered ready to use. All you need to do is attach plywood to the aluminum profiles.

“After we receive an inquiry for a door or window opening, for instance, our engineering department draws a mold for it. We cut and pre-drill aluminum profiles according to the drawing you have approved. Then we attach the parts and put corner pieces in the corners of the mold to make exact 90-degree angles”, Makhmour says.

“We want to be challenged in new ways. When you have a new type of need, we will sit down together to come up with unique ways to utilize existing solutions. Often, we will create new ones. It is an ever-evolving field, and we enjoy inventing creative solutions”, Makhmour adds.

Elematic FaMe Magnet Shuttering

A unique, patented shuttering system.

The system consists of light aluminum profiles, various types of magnets and planning software for creating drawings and bills of materials.

FaMe can be used with table and battery molds, and in beam and column production.

The system is modular so you can start with a limited number of components first and build the system later.

Elematic FaMe shuttering system

FaMe solutions for different mold preparation applications

Order our newsletter or contact us!

or