The precast industry, despite its long tradition in the western world, is still taking its first steps in industrial design. Elematic, however, has been combining engineering and industrial design for 20 years.

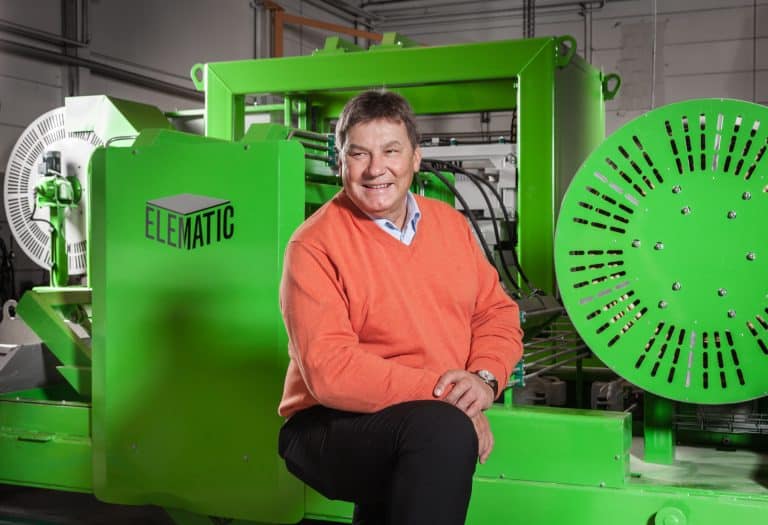

“In the early 1990s, our new extruder was to be introduced at an exhibition. We realized it should somehow stand out from the level of machinery that people were used to,” says Lassi Järvinen, the Technical Director of Elematic. At that time, they ended up developing the extruder in cooperation with a design company.

“It really made a difference. Introducing an appropriate and functional yet smooth and stylish extruder disarmed our critical audience of precast professionals. No doubts were raised about the functionality of the machine.”

A couple of years later, the need for a reliable, long-term partnership became apparent. The company began searching for a diversified design team with international experience.

A local Finnish design agency, Muodonmuutos (Transformation), was chosen because of its convincing experience with other international high-quality machine builders such as John Deere, Sandvik, and Fiskars. Over the years, this has proved to be a good choice. The close co-operation between Elematic and Muodonmuutos has been fruitful.

“Tapani Holma and his designers have given our engineers a lot of new perspectives during the past decades. Major steps have been taken since the days when precast machinery components were roughly welded together,” Järvinen says.

The tools for industrial design have naturally evolved through the years. 20 years ago it was all about pen-drawn sketches and models made from various materials. Today most of the work is done in 3D with computers.

“The new laser-cutting technology has made it possible to utilize various shapes in machine design. It has also decreased the production costs. The production material, steel, is still the best choice in precast machinery. In this industry, the weight and solidity of the material are a benefit,” explains Tapani Holma, designer and partner in Muodonmuutos.

In precast, the quality of the end product and production effectiveness count. But it often takes more to convince customers. “Precasters need reliable machinery that can produce just the right quantities of high-quality products. However, the physical appearance counts too.

“A properly designed product is easy and safe to use, and works as intended. The design takes into account the space where the machinery is placed, the people working with it, the maintenance operations, and the production of the machine. Functionality in precast machinery means that monitoring and control devices and tools are placed optimally from the users’ and maintenance personnel’s point of view. Also, safety is the sum of several factors. Guardrails and a well-considered place for the safety switch are obvious examples of factors that increase safety. However, the beautiful, plain surface of the machine is for safety, too. It prevents users from getting their clothes caught on the machine,” Järvinen explains.

“It is essential for a designer to understand the precast production process and the end use of the product. The design of a product is always a result, not a goal,” underlines Holma.

In order to build a strong relationship with their customers, precasters often invite them to visit the factory. Good-looking, high-quality machinery in a well-organized factory builds an image of professional production and know-how.

“We want Elematic to be easily recognized, streamlined, and convincing. However, the design always starts with usability and production requirements,” says Holma.

Both Järvinen and Holma have noticed that design affects the way people handle the machine.

“A well-designed machine encourages people to take better care of it. Maintenance is taken more seriously, and training is invested in. The machinery is considered a valuable investment, not just a necessary tool.”