Eurobend: Modern rebar processing and welding machinery lines for all precast applications

Eurobend offers the most comprehensive range of rebar processing and welding equipment covering every precast application. Their portfolio of more than 100 machine types includes 2D and 3D rebar benders as well as single line and multi-line straightening and cutting machines.

Eurobend’s modular welding lines can be adapted easily to the individual demands of any precast company or application. The welding lines are the preferred choice of a large majority of precast companies throughout the world, and Rotor Straightening — a method invented by Eurobend — is the most popular straightening method worldwide.

Until now, all straightening machines have used either straightening rotors with dies or a two-plane straightening roller configuration. Both methods have their individual shortcomings. In the first method, the friction generated between the wire and the dies damages the wire surface. Due to premature wear of the dies, continuous adjustments to achieve acceptable straightening are unavoidable. In the second method, the straightening is of poor quality.

Eurobend’s method is to use a rotating arbor — a rotor — but instead of dies, there are either six or eight hyperbolically profiled steel rollers. Rotation of the arbor around the wire forces the wire to move forward, since all the rollers are set to an angle in relation to the wire axis. This technique enables frictionless, simultaneous straightening and feeding. The method offers perfect straightening results, eliminating the disadvantages of the two previous straightening methods.

“Today, our 4th generation Rotor Straighteners are the top-of-the-range choice for straightening every type of wire and rebar,” says Anthony Anagnos, President of Eurobend.

According to Eurobend, the popularity is based on effective solutions, reliability, and profitability.

Unique machinery

Eurobend’s MELC Rotor straightening machines can be used as stand-alone straightening systems, but they can also be a part of combined straightening, cutting and bending rebar processing centers, or function as a feeding system for mesh welding lines, such as the PLC AMM Series.

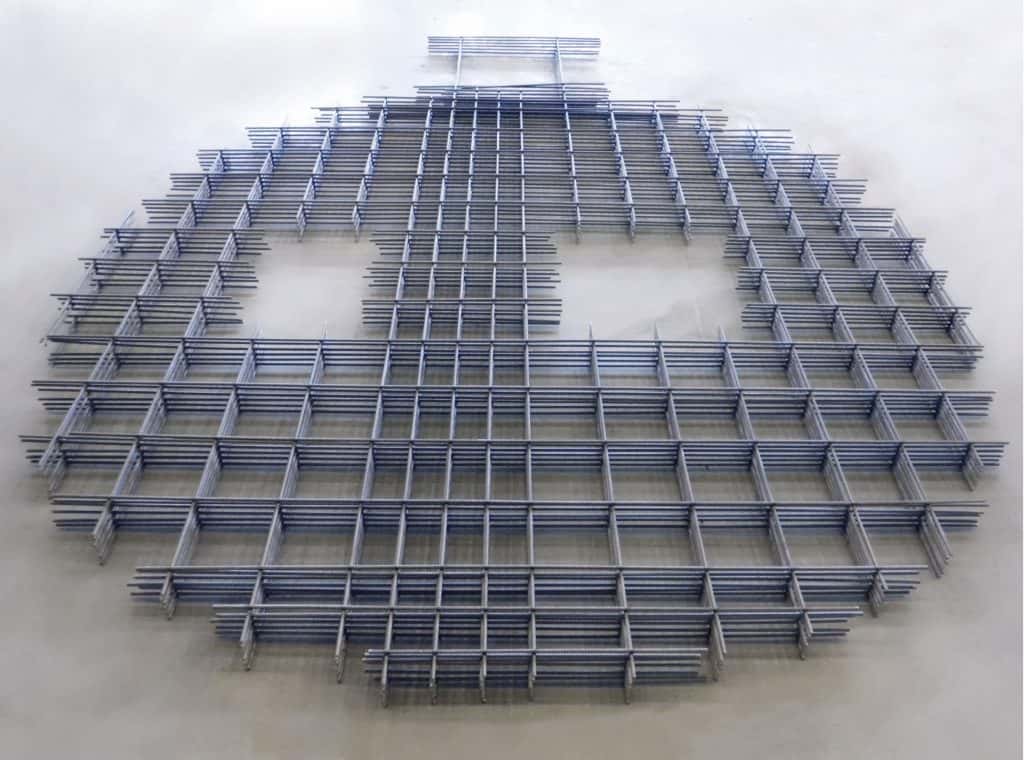

The PLC AMM series is a fully automated line to produce customized mesh. The series covers every application in the production of engineering, construction, and customized mesh, and mesh with openings for prefabricated concrete elements.

“The PLC AMM Series can produce large and small batches-orders consecutively without any downtime. They are the fastest machines of this type on the market,” says Isabel Protopapa, Managing Director.

Eurobend has patented their wire feeding system. With the fully automatic wire changing features of the Flexi-Line MELC straightening and cutting machines, any type of mesh can be produced instantly without any adjustments.

User-friendly philosophy

The modularity and flexibility of Eurobend’s machine designs have allowed the company to serve the worldwide precast market with success.

“We have invested in user-friendly operation, simple machine layout and minimal maintenance requirements. It is our principle to actively react to industry demands and always stay one step ahead of the competition,” says Protopapa.

By introducing new ideas and solutions, Eurobend provides innovative equipment that focuses on the customers’ growth. This makes Eurobend the leader in their market sector. According to Anagnos, the reputation and popularity of the products stem from Eurobend’s core values: continuous improvement using the latest cutting-edge technology, uncompromised quality on all components, and prompt after sales support.

“The diversification, new ideas, and solutions that our machines offer all help us to continuously expand and grow. By making new collaborations and launching new machines, we are positive that we can serve our customers even better in the future,” says Anagnos.

“We have invested in user-friendly operation, simple machine layout and minimal maintenance requirements. It is our principle to actively react to industry demands.”