Digital situation pictures will speed up construction

In the future, all necessary information at a construction site may be checked from a shared DSP. What exactly is a digital situation picture, and how can DSPs make construction processes faster?

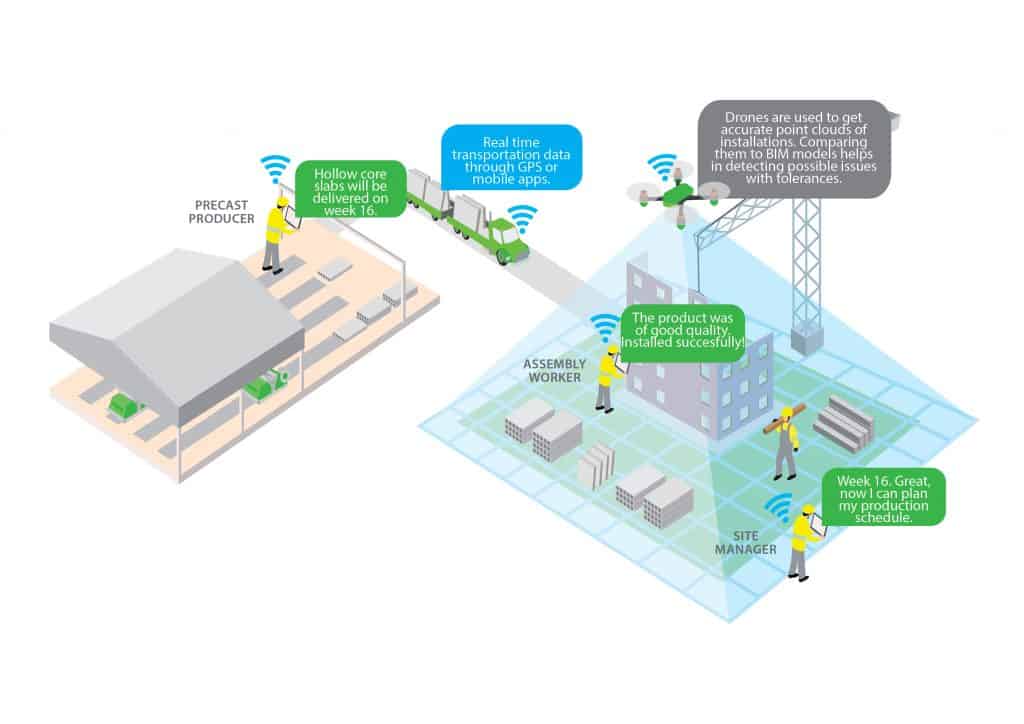

Digital situation pictures do not exist yet, but they are a thing of the future. A DSP is a real-time situation picture of a construction project, entailing data about the past, current and future activities of the project. Context-specific data will be available in a real-time digital format, which means that the owner, designers, contractors, and fabricators of a construction project will have access to information that is relevant for them at any time and place.

The benefits of DSPs could be enormous to the construction sector. Project parties could make decisions and plan their future activities based on accurate data. Project schedules would become shorter, quality would improve, and misunderstandings could be avoided.

Right now, researchers are trying to create a shared data structure for DSPs. There are still some questions unanswered, such as what data will be included and how will it be shared between project parties. But DSPs will combine information from different sources concerning the intended end-product, material logistics, resource movements and supply chain. The data will staple together BIM (Building information modelling), simulations, ERP systems, IoT sensors, indoor positioning systems, photos, point clouds and onsite communication.

How can a precast concrete factory prepare for the digital future?

IN THE PAST: Lots of questions on site

Workers could add value to the project only in 1/3 of their working time. They spent 2/3 of the time searching for their tools, materials, and work locations. And wondering what they were expected to do.

IN THE FUTURE: Lots of real-time information on site

Workers know where they are supposed to work, where they can find their materials and tools, what was the preceding task, and what is the current work plan.

A digital situation picture leads to…

Less confusion,

Faster material and tool handling,

Workers concentrating on value-adding work,

Productive projects,

Fewer misunderstandings,

Less quality problems.