Have you calculated ROI for your shuttering system?

When choosing a shuttering system, it is typical to look at the initial investment and pay less attention to future cost savings. However, you can save a lot of time and money by using a flexible shuttering system with lightweight and long-lasting formwork elements.

Wouldn’t it be handy if your shuttering system’s side profiles could be moved by a single employee without a crane or any other mechanical transport? Elematic shuttering system comes with light aluminum side profiles, which significantly reduce the weight of the mold compared to steel profiles. This not only makes work easier, but also safer.

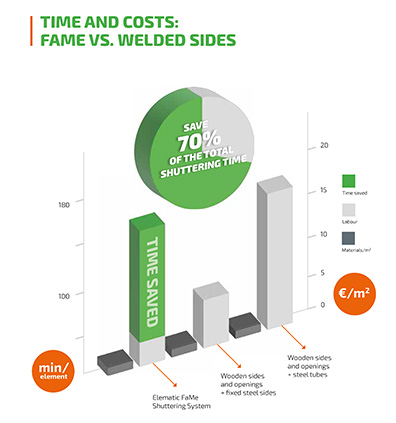

A flexible system saves time and money

If you choose your shuttering system wisely and pay attention to fastening method, for example, it can be a really profitable investment. Make sure that no welding is needed and that it is easy to prepare the mold and adjust the height and thickness of side profiles – with Elematic system you can even make doors and windows with the same profiles.

For example, if you are making 150m thick elements, but suddenly the thickness of the elements needs to be increased, you can reach 300mm with the same profile just by adding plywood and heightening support.

Aluminum profiles allow you to save significantly on plywood costs. This also means that you don’t have to spend time buying or cutting wood. We’ve been amazed at how much work many factories have put into cutting plywood. Our system can immediately bring a big change to this workload!

Writer

Paul Görner, Sales Engineer, Shuttering

Let others enjoy this blog too!

Red is now green — premium quality remains

Elematic shuttering system has a really long lifespan. If you handle magnets as instructed, they can easily last for decades. Magnets used to be red, so we know from their color that some of our customers are still using magnets that are more than 15 years old.

Rust-resistant aluminum profiles also last for many years when kept clean. You have to buy new ones only if you cut them and there is always the possibility of combining shorter pieces into longer parts.

The overall cost is also affected by the fact that the system is easy to repair and reuse. If you have an issue with any part of Elematic system, you can have it serviced or repaired – spare parts are available in stock.

Start with small steps and still see the benefits

If you are looking for a flexible system update within a certain budget, you can first introduce the shuttering system for a single casting table. This allows you to compare it to your existing solution.

It is even possible to start with magnets and only later switch to aluminum side forms. It is easier to invest more when you have seen the benefits.